A New Framework for the Next Generation of Procurement: Beyond Cost Savings

January 30, 2026 | By Jabil Procurement & Supply Chain Team

Procurement teams are navigating a landscape where volatility is no longer the exception; it is the operating baseline.

Recent research shows that nearly 63% of companies have suffered higher-than-expected losses from supply chain risks, while fewer than one-in-ten feel fully in control of those exposures. Inflation swings, geopolitical shocks, climate-related events, and regulatory shifts now collide with compressed planning cycles and rising stakeholder expectations.

Against that backdrop, the old “lowest price wins” playbook is breaking down. Squeezing suppliers on unit cost often concentrates spend with a single source, extends lead times, and strips redundancy out of the network. The headline savings rarely account for premium freight, last-minute expedites, write-offs from excess or obsolete inventory, or the revenue lost when a critical component is late. What looks like efficient procurement on paper can translate into fragile supply, volatile margins, and damaged customer relationships in practice.

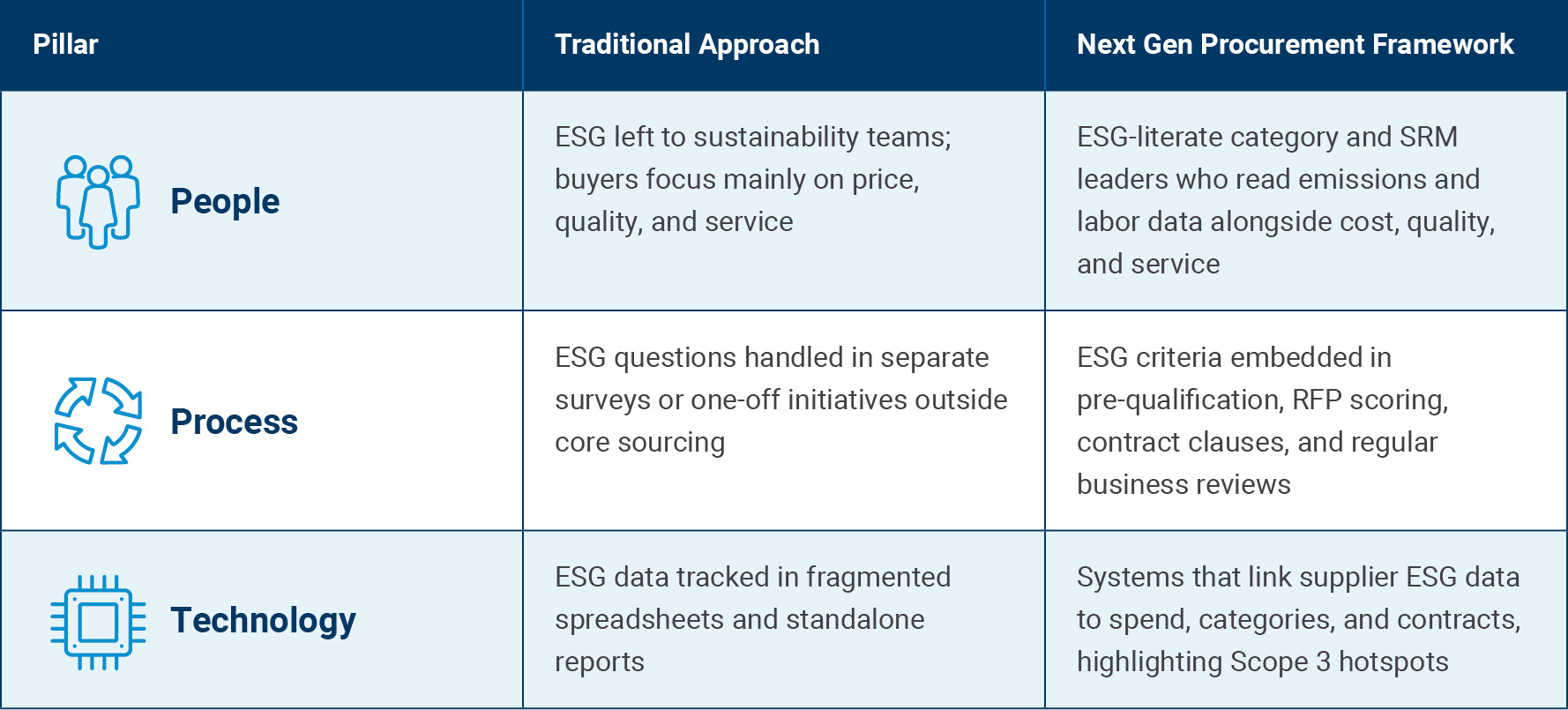

The framework for the next generation of procurement starts from a different premise. Instead of treating cost, resilience, and sustainability as competing priorities, it organizes procurement around three core pillars: people, process, and technology. Done well, this same framework becomes a sustainable sourcing model, embedding ESG outcomes into day-to-day decisions rather than bolting them on as an afterthought.

Why The Old Procurement Playbook Is Breaking

Climate Shocks

99% of supply chain leaders report climate impacts.

Geopolitics & Trade

Tariffs and conflicts disrupt 20–40% of supply chain activity.

Cyber Risk

Average data breach (USD): $4.44M globally and over $10M in the U.S.

The old procurement playbook was built for a world where risk was episodic and mostly predictable. That world has shifted. Disruption now comes from cyberattacks, geopolitical shocks, supplier failures and extreme weather, often hitting simultaneously and deep in the value chain.

- Climate and infrastructure shocks: More than 99% of supply chain executives say climate change is already impacting their supply chains. Weather events such as heavy rains and flooding in California, Nevada, and Utah have cut shipments by 20-30% in the past, while smoke from Canadian wildfires delayed deliveries into Chicago and New York by up to two days and reduced volumes by as much as 75%.

- Geopolitical and trade disruptions: Roughly 82% of companies report their supply chains have been affected by new tariffs, with 20-40% of activity disrupted in some way. The Russia–Ukraine conflict alone has driven an estimated 35% drop in Ukrainian agricultural output and more than US$1.6 trillion in global supply chain inefficiencies.

- Cyber risks: The average cost of a data breach is roughly US$4.44 million globally and more than US$10 million in the United States, higher than any country or region. Hyperconnected networks make cyberattacks harder to contain; with 16% of organizations identifying cyber risks as their top supply chain concern.

A cost-driven, event-based sourcing model cannot handle these pressures. The next section introduces the three-pillar framework, people, process, and technology, to align procurement with resilience, agility and sustainability.

Pillar One – People: From Buyers to Data-Savvy Diplomats

Next gen procurement starts with people. Traditional buyer profiles, built around price negotiation and policy enforcement, cannot keep pace with a world where boards expect procurement to manage risk, resilience, ESG, and innovation alongside savings. The real question is no longer if the talent model must evolve, but toward what.

What “data-savvy diplomats” really do

In a framework for the next generation of procurement, high performers are no longer just strong negotiators. They operate as “data-savvy diplomats” who can:

- Read the numbers. Interpret spend cubes, scenario models, and risk dashboards well enough to challenge assumptions, not just admire charts.

- Translate strategy into sourcing. Hold credible conversations with finance, operations, and commercial leaders, then turn their goals into sourcing strategies, contracts, and supplier portfolios.

- Lead with suppliers, not just police them. Co-design innovation roadmaps, service models, and ESG journeys with strategic partners rather than running one-off RFPs.

This combination of analytics fluency and stakeholder diplomacy is what allows procurement to move from “lowest price” to “best value under defined risk and ESG constraints.”

Capabilities next-gen teams need

To make that shift real, next gen procurement talent needs a practical toolset:

- Digital fluency. Comfortable working inside procurement digital transformation platforms, P2P suites, workflow automation, and SRM tools, rather than treating them as IT’s domain.

- Risk and ESG literacy. Able to use cyber, supply risk, and emissions data as live inputs in negotiations, supplier scorecards, and contract language.

- Cross-functional storytelling. Confident explaining how a sourcing decision will move gross margin, resilience, and Scope 3 emissions at the same time, in language each stakeholder understands.

How to build the people layer

There is no single path to this people layer of the framework for the next generation of procurement. Leading organizations typically blend three moves:

- Upskill the core team with focused academies on analytics, automation, and ESG.

- Recruit hybrid profiles (ex-operations, data, or sustainability specialists) directly into category and supplier-management roles.

- Stand up a small center of excellence for analytics and sustainability that supports category managers while new skills mature in the line organization.

Taken together, these moves turn procurement from a team of skilled buyers into a bench of data-savvy diplomats, setting up the process and technology pillars to deliver much more than unit-price savings.

Pillar Two – Process: Building Agile, Risk-Aware Ways of Working

Most procurement teams have updated their tools and policies, but not their underlying ways of working. The result is familiar: new dashboards feeding into old, linear workflows. Sourcing still runs in long cycles, approvals still move in sequence, and risk is still treated as an exception, not a design parameter. In a world of rolling disruption, many organizations are optimizing yesterday’s process, rather than redesigning it for volatility.

From linear workflows to scenario-based orchestration

An agile process layer turns procurement from a slow, event-driven function into a continuous, scenario-driven one. Instead of treating each sourcing event as a one-off project, teams work from modular playbooks that can be reused, adapted, and accelerated when conditions change.

In practice, agile procurement can look like:

- Short, iterative sourcing cycles: Smaller, faster events with pre-built playbooks for disruption (e.g., rapid rebids, alternate-supplier activation, temporary contract bridges).

- Embedded risk and ESG checkpoints: Risk, compliance, and sustainability reviews built into each stage of source-to-contract and procure-to-pay, not bolted on at the end.

- Cross-functional “war rooms”: Fast-spin-up forums where procurement, operations, finance, and legal can make time-bound decisions when supply, geopolitical, or compliance risks spike.

Examples of agile supply chain processes

Behind those workflows sit rules that can flex as conditions change, rather than static policies that assume stability.

- Dynamic safety stock and dual sourcing: Target buffers, lanes, and second-source allocations that adjust based on risk indicators, not annual planning assumptions.

- Supplier segmentation tied to sustainable sourcing: Differentiated treatment for strategic partners willing to co-invest in resilience and decarbonization versus purely transactional vendors.

Choosing the right operating model

Process agility also depends on how governance and decision rights are structured. There is no single “correct” model, but successful frameworks tend to balance control with flexibility:

- Centralized governance: Standards for risk, ESG, data, and category policies set at the center to ensure consistency and compliance.

- Local flexibility: Regional or business-unit teams empowered to make tactical buys, adapt playbooks, and collaborate closely with local suppliers.

This is the process backbone of a practical procurement maturity model. Without agile, risk-aware ways of working, even the best people and technology cannot deliver the full promise of a framework for the next generation of procurement.

Pillar Three – Technology: The Digital Core Behind the Next Generation of Procurement

Procurement leaders are not short on ideas, they’re short on capacity. Too much time is still spent reconciling spreadsheets, chasing stakeholder approvals, and stitching together data from multiple systems. The digital core behind a framework for the next generation of procurement is what reverses that balance.

When automation, analytics, and integration are designed as one cohesive stack, technology stops being “another system to manage” and becomes the engine that powers faster decisions, cleaner execution, and more resilient supplier strategies. To turn technology into a true advantage, procurement needs a focused, practical approach:

- Anchor on a true digital core. Define a single data model for suppliers, categories, contracts, and risk, and connect ERP, sourcing, P2P, logistics, SRM, and ESG tools into one backbone instead of separate islands of data.

- Automate the transactional layer first. Use e-sourcing, guided buying, catalogs, and invoice workflows to handle routine, low-risk activity with minimal human touch so teams can reclaim time for category strategy and supplier relationships.

- Turn reporting into decision intelligence. Replace static reports with interactive spend analytics, risk dashboards, and simple “what-if” views that let a category manager see the cost, risk, and ESG impact of different sourcing scenarios in seconds.

- Bake risk and ESG into every workflow. Configure systems so that supplier scorecards, risk checks, and sustainability criteria appear inside the sourcing and contracting process, not as offline spreadsheets or after-the-fact reviews.

- Invest deliberately in data quality and governance. Assign clear ownership for supplier and contract data, standardize taxonomies, and set pragmatic rules for when data is clean enough to automate versus when it needs human validation.

- Define the boundary between machine and human decisions. Establish thresholds for auto-approvals, auto-reorders, and exception handling, and make it explicit where human judgment is required, for negotiations, innovation bets, complex risk trade-offs, and strategic supplier moves.

- Choose a deployment path that matches your procurement maturity. Smaller organizations may prioritize modular, cloud-based tools that can scale gradually, while larger enterprises may layer advanced analytics or digital-twin capabilities on top of existing platforms rather than starting from scratch.

Approached this way, technology stops being “another system to feed” and becomes the digital core of next gen procurement: an automation and insight engine that lets people and processes focus on margin, resilience, and sustainable value creation instead of transactional firefighting.

Sustainability as a Built-In Outcome, Not an Add-On

Procurement now sits at the center of corporate sustainability. For many enterprises, value-chain emissions are far higher than those from their own operations, with supply chain–related Scope 3 often more than twenty times direct emissions. In that context, the framework for next gen procurement is not just about managing cost and risk, it becomes the day-to-day system for delivering climate and social outcomes at scale.

At a glance, each pillar of the framework shifts in specific ways that translate directly into ESG impact:

People: ESG-Literate Category Leaders

In a next gen model, category managers and SRM leads are expected to read emissions data and labor indicators as fluently as they read price curves. That means:

- Translating high-level climate commitments into practical supplier expectations for specific categories.

- Using supplier scorecards that weight Scope 3, labor practices, and circularity alongside cost, quality, and service.

- Leading nuanced conversations with suppliers about transition plans, not one-off questionnaires about “green” credentials.

The “data-savvy diplomat” profile becomes even more critical here: someone who can reconcile commercial targets with sustainability objectives and explain the trade-offs in clear business terms to finance, operations, and sustainability stakeholders.

Process: A Sustainable Sourcing Framework by Design

Sustainability becomes real when it is wired into everyday workflows. An agile, risk-aware process evolves into a sustainable sourcing framework when:

• ESG criteria appear in supplier pre-qualification, RFP templates, and evaluation rubrics, not in separate side documents.

• Contract language routinely covers science-based targets, recycled or renewable content, take-back programs, or waste-reduction commitments where material.

• Business reviews with strategic suppliers treat emissions, human rights, and community impact as standing agenda items, not annual add-ons.

Over time, the same procurement maturity model used to track cost and risk can be extended to ESG: teams do not get full credit for “savings” if those savings are achieved by increasing carbon exposure or social risk.

Technology: Making ESG Measurable and Actionable

Technology is what turns ESG ambition into traceable performance. Modern procurement systems should be able to:

- Capture supplier ESG data (from disclosures, audits, and third-party feeds) and link it directly to spend, categories, and contracts.

- Highlight hotspots where a small number of suppliers or materials drive a disproportionate share of emissions.

- Support external reporting and customer requests without manual spreadsheet archaeology.

For many teams, the best approach is to start with two or three high-impact categories (for example, logistics, packaging, or energy-intensive inputs), prove that the new framework can deliver both cost and carbon improvements, then scale. When people, process, and technology are aligned this way, sustainable, resilient value creation becomes the default outcome, not a separate ESG project fighting for attention.

Partnering with Jabil to Build Your Framework for the Next Generation of Procurement

The era of “lowest price wins” has passed. The framework for the next generation of procurement is not a trend; it is a way to make procurement resilient, repeatable, and tied directly to value creation. It rests on three pillars: a talent base of data-savvy diplomats, agile and risk-aware processes, and a digital core that automates the transactional while elevating the strategic.

When those elements work together, procurement stops acting as a back-office function and starts operating as a control point for margin, resilience, and sustainability. Supplier choices, specifications, and contracts are no longer driven by unit cost alone, but by a balanced view of risk, total cost, service, and ESG impact. Over time, that shift compounds into stronger earnings, fewer surprises, and a more credible story for boards, investors, and customers.

Jabil works with procurement and supply chain leaders to design and operationalize this framework end to end, linking people, process, and technology with measurable outcomes in cost, risk, and ESG. To explore what that could look like for your organization, connect with the Jabil team.