End-to-End Logistics Management: From First Mile to Final Delivery

July 9, 2025 | By Jabil Procurement & Supply Chain Team

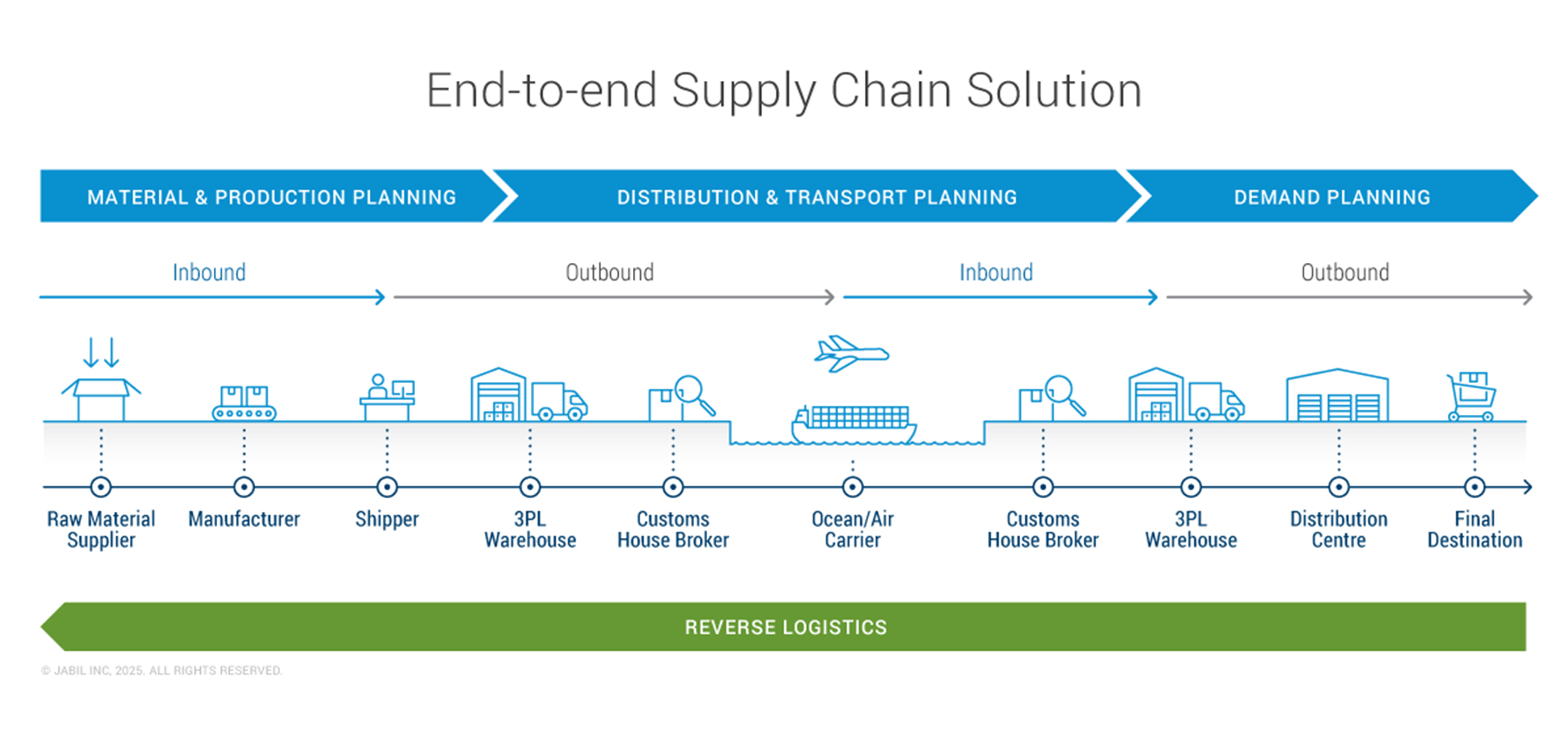

At Jabil, we’ve seen firsthand how every product journey tells a story, beginning with raw material sourcing, continuing through manufacturing and transportation, and concluding with final delivery or even return. Managing that journey isn’t just a logistical function; it’s a critical driver of operational performance, customer satisfaction, and long-term competitiveness.

As a global manufacturing and supply chain leader supporting some of the world’s most complex enterprises, Jabil understands what it takes to manage logistics at scale. Our approach to end-to-end logistics management brings structure to that story by aligning procurement, warehousing, freight, inventory, and fulfillment into a unified system, one designed for speed, transparency, and control. Rather than managing logistics in disconnected silos, we help companies build integrated frameworks that enhance visibility, streamline decisions, and reduce risk across every stage of the supply chain.

This strategic approach has become essential for navigating today’s global networks, adapting to shifting demand, and meeting growing sustainability goals. It's not just about moving products efficiently; it's about designing intelligent systems that anticipate disruption, scale with demand, and create value at every handoff.

What is End-to-End Logistics Management?

For global enterprises, end-to-end logistics management is about more than overseeing individual supply chain functions. It's about synchronizing them into one adaptive, data-informed system. As international sourcing, multimodal transportation, and omnichannel fulfillment grow increasingly interdependent, organizations need unified strategies that align physical movement with procurement planning, risk mitigation, and customer service.

At its core, end-to-end logistics connects every operational layer, turning fragmented workflows into a coordinated engine for resilience, responsiveness, and efficiency. To build this level of integration, organizations must align several foundational components that drive logistics performance from start to finish. These include:

Procurement and Supplier Management

Selecting and managing global suppliers is essential to ensure timely, compliant sourcing of raw materials and components. To reduce risk exposure and maintain continuity, companies are turning to multi-sourcing strategies and long-term supplier partnerships that can provide greater lead time reliability during periods of disruption.

Manufacturing and Production Planning

Coordinating production schedules and capacity planning helps align manufacturing output with demand signals and reduce costly bottlenecks. Integrated planning tools enable companies to adapt quickly to market changes, minimizing downtime and excess inventory while improving throughput across facilities.

Inventory and Warehouse Management

Balancing stock levels, storage efficiency, and fulfillment speed is critical for operational agility. Real-time inventory tracking and automated warehousing systems are giving logistics teams greater accuracy, faster cycle times, and fewer touchpoints—helping reduce costs while ensuring the right products are available when and where they’re needed.

Transportation and Distribution Networks

Orchestrating multimodal transport, carrier selection, and route optimization reduces both lead times and logistics spend. More organizations are adopting dynamic routing and mode-shifting capabilities to respond to traffic patterns, weather events, and market volatility while maintaining service levels across the last mile.

After-sales Service and Reverse Logistics

Managing returns, repairs, and recycling with transparency is a growing part of delivering end-to-end value. A well-designed reverse logistics system can improve customer satisfaction, support sustainability goals, and generate actionable insights from return trends and service data.

How Does End-to-End Logistics Management Work?

End-to-end logistics management functions by integrating each link in the supply chain through a centralized digital infrastructure.

This allows logistics leaders to monitor and coordinate procurement, production, inventory, fulfillment, and returns as a unified system, rather than isolated operations. The result is real-time responsiveness, fewer handoff errors, and greater control over service levels and cost performance.

The Role of Technology

Technology is the foundation that enables end-to-end logistics to operate with speed, scale, and precision. Without digital tools, managing global logistics across multiple tiers and partners would be fragmented and reactive.

From predictive analytics to warehouse robotics, the following innovations are transforming how logistics teams plan, monitor, and execute across the supply chain:

Real-Time Tracking and Visibility

IoT sensors and GPS-enabled freight tracking deliver up-to-the-minute status on inventory, vehicle locations, and warehouse conditions. This visibility allows teams to respond immediately to delays or disruptions, such as rerouting a shipment around a weather event or preventing spoilage of temperature-sensitive goods.

Predictive Analytics and Demand Forecasting

AI and machine learning tools analyze historical and real-time data to forecast future demand trends, production bottlenecks, and supply risks. For instance, retailers can dynamically adjust distribution volumes based on regional buying patterns or seasonality.

Blockchain for Transparency and Security

Distributed ledger technology ensures data integrity and product authenticity by recording every transaction in a secure, tamper-proof system. This is especially valuable in industries like pharmaceuticals or luxury goods, where provenance and regulatory compliance are critical.

Automation and Robotics in Warehousing

Automated guided vehicles (AGVs), robotic picking systems, and dynamic storage technologies streamline fulfillment and reduce labor dependency. A single robotic system can pick and pack thousands of SKUs per hour with near-perfect accuracy, improving efficiency and scalability.

Importance of Data-Driven Decisions in Logistics Optimization

The shift from reactive logistics to predictive, data-driven management is the key to streamlining modern supply chains. Companies are no longer making decisions based on static reports. They’re relying on real-time intelligence to drive continuous improvement and long-term performance.

Core Data-Driven Functions

Here are three core areas where data is reshaping how logistics teams plan, respond, and optimize across operations:

- Inventory Optimization: Advanced analytics help balance inventory levels against lead times, demand variability, and carrying costs. For example, a manufacturer can avoid overstocking raw materials by monitoring supplier delivery patterns and aligning purchases with production schedules.

- Smart Routing: Real-time traffic data, fuel price trends, and vehicle telemetry feed into AI-powered route planning tools that minimize idle time and emissions. A logistics team might automatically reroute drivers to avoid congestion and reduce delivery windows by hours.

- Integrated Forecasting: When forecasting systems are connected across procurement, logistics, sales, and customer service, organizations can plan more effectively. Data-backed insights, such as Jabil’s Market Intelligence reports, can warn companies of market shifts, component trends, and potential supply risks before they impact operations.

Benefits of Implementing End-to-End Logistics Management

When organizations integrate logistics operations from sourcing to delivery, the results cascade through efficiency, cost, service, and sustainability metrics. Here are the core benefits driving adoption across industries.

Enhanced Operational Efficiency

Integrating procurement, production, warehousing, and distribution into a cohesive logistics strategy eliminates redundancies and streamlines workflows across departments. This holistic coordination reduces lead times, improves production scheduling, and minimizes excess handling.

For example, real-time synchronization between demand signals and warehouse operations allows companies to move inventory with precision, avoiding unnecessary delays and labor.

Significant Cost Savings

Efficient logistics systems translate directly to lower operating costs. End-to-end visibility enables companies to optimize route planning, consolidate shipments, and reduce fuel expenses, especially critical for long-haul or multi-modal transportation. Over time, these savings can contribute millions to the bottom line for large-scale operations.

Improved Customer Satisfaction

Customers now expect fast, reliable, and transparent delivery experiences. Integrated logistics systems make it easier to fulfill orders accurately and on time, enhancing trust and loyalty. They also simplify reverse logistics processes, enabling smooth returns and warranty servicing. For instance, a retailer using end-to-end logistics can offer real-time delivery tracking and rapid returns, giving it a competitive edge in customer satisfaction and retention.

Increased Supply Chain Visibility

End-to-end systems break down the silos that often obscure logistics performance. With access to real-time data across every stage of the supply chain, decision-makers can spot disruptions early, respond to bottlenecks proactively, and hold suppliers accountable to performance standards.

Enhanced visibility also strengthens compliance efforts by providing auditable records of shipments, sourcing practices, and quality checks, especially important in regulated industries. By leveraging Jabil’s Supply Chain Consulting services, companies can uncover blind spots, improve visibility, and gain tighter control across complex, multi-tier logistics networks.

Scalability and Flexibility

As markets shift and demand fluctuates, logistics operations must remain agile. End-to-end management supports rapid scaling without sacrificing efficiency by using modular systems and shared data frameworks that adapt to new geographies, volumes, or business models. For example, a business expanding into new markets can quickly onboard regional suppliers and 3PLs using the same integrated logistics platform, ensuring continuity, speed, and service quality.

Sustainability and Environmental Responsibility

A more efficient logistics operation is inherently greener. Consolidating loads, reducing idle times, and optimizing warehouse footprints all reduce emissions and resource use. But beyond operational efficiency, companies are using logistics to differentiate their brand and meet environmental, social, and governance (ESG) goals. For instance, sustainability dashboards now help teams model the carbon impact of different delivery options, allowing them to choose the most environmentally responsible path forward.

How to Effectively Implement End-to-End Logistics Management

Implementing end-to-end logistics management requires more than just new technology. It demands a structured, strategic shift in how supply chains are assessed, connected, and optimized.

Step 1: Conducting a Comprehensive Supply Chain Audit

The first step toward successful implementation is a thorough audit of your current supply chain. By mapping existing processes across procurement, manufacturing, warehousing, and distribution, organizations can identify gaps, inefficiencies, and siloed operations that hinder end-to-end performance.

Evaluating your technology stack is equally important, many companies discover that their existing tools don’t support the real-time data or cross-functional visibility needed for modern logistics. An audit sets the stage for transformation. Jabil’s Procurement Consulting services can help benchmark performance and identify strategic areas for improvement.

Step 2: Integrating Technology and Automation

Technology is the backbone of end-to-end logistics management. Choosing the right platforms, such as transportation management systems (TMS), warehouse management systems (WMS), and supply chain control towers, can drastically improve efficiency and coordination. Integration of IoT sensors allows for real-time asset tracking, AI improves demand forecasting, and blockchain ensures secure data sharing and traceability across partners.

Step 3: Building Collaborative Supplier and Partner Relationships

End-to-end logistics doesn’t stop at the warehouse gate. It depends on alignment across your entire supplier ecosystem. Building strong, collaborative relationships with suppliers, logistics providers, and distributors requires a shared commitment to performance, quality, and sustainability.

Companies that co-invest in shared data platforms and performance dashboards often gain faster response times and fewer disruptions. When partners have visibility into real-time demand or shipment delays, they can adjust upstream processes accordingly, improving the entire chain’s responsiveness.

Step 4: Training and Change Management

No transformation succeeds without people. Implementing an integrated logistics model requires comprehensive training for procurement, logistics, and operations teams. From learning new digital platforms to adopting best practices in data use and cross-functional planning, training should be embedded at every level.

Equally important is change management. Leaders must foster a culture of transparency, collaboration, and continuous improvement to minimize resistance and ensure smooth adoption. Empowered teams are better equipped to spot issues early, take ownership of KPIs, and adapt to future innovations.

Common Challenges in End-to-End Logistics Management

While end-to-end logistics offers clear strategic advantages, implementing it at scale presents a range of operational and organizational challenges that must be proactively addressed.

- Technology Integration Issues: Many organizations struggle to connect fragmented legacy systems and data silos, creating roadblocks to real-time visibility and automation.

- Lack of Unified Data Standards: Disparate systems and inconsistent data formats make it difficult to synchronize supply chain activities across partners and platforms.

- Managing Global Complexity: Varying regulations, customs procedures, and compliance requirements across countries complicate logistics standardization and scalability.

- Process Inconsistencies Across Regions: Different teams and partners often use non-standardized workflows, leading to inefficiencies and gaps in execution.

- Cost and Resource Constraints: High upfront investments in systems, infrastructure, and skilled labor can deter businesses from adopting fully integrated logistics strategies.

- Workforce Readiness and Training Gaps: Implementing advanced logistics systems requires teams to adapt quickly, often without sufficient training or change management support.

- Vendor and Supplier Misalignment: Misaligned performance metrics, sustainability goals, or digital maturity levels between stakeholders can disrupt flow and coordination.

- Limited Visibility Beyond Tier-One Suppliers: With only 60% of companies reporting full visibility into their tier-one suppliers, most organizations remain exposed to hidden risks and upstream bottlenecks.

- Disruption and Risk Management: From extreme weather events to geopolitical tensions, companies must proactively prepare for disruptions that can paralyze logistics operations.

- Sustainability Trade-offs: Balancing speed, cost, and environmental impact is increasingly difficult, especially in regions lacking green infrastructure.

Why End-to-End Logistics is Essential for the Future

End-to-end logistics management is the strategic foundation for future-ready supply chains. As complexity rises and expectations sharpen, companies that adopt a holistic, integrated approach are better equipped to reduce costs, adapt quickly, and deliver superior customer experiences.

By aligning every logistics function under a single system, businesses unlock the visibility, speed, and control needed to stay competitive in a rapidly evolving marketplace.

Partner with Jabil for End-to-End Logistics

Looking to modernize your logistics operations?

Connect with Jabil’s procurement and supply chain experts to explore how our complete solutions can help you optimize performance, boost resilience, and lead with confidence. Schedule a consultation today.