End-to-End Procurement: A Strategic Framework for Modern Supply Chains

July 18, 2025 | By Jabil Procurement & Supply Chain Team

Today’s leading companies treat procurement as a competitive advantage, not just a back-office function. Modern procurement goes beyond buying goods and services, it builds resilient supply chains, drives cost savings, and unlocks innovation through strategic supplier partnerships.

This evolution reflects a fundamental truth: in an interconnected global economy, what you buy determines how you compete.

End-to-end procurement addresses this challenge by connecting all supply chain activities into one continuous, intelligent system. This approach breaks down traditional silos between sourcing, supplier management, and operations. The result is greater visibility, stronger partnerships, and the agility to adapt to changing market conditions.

Companies that master this approach don't just reduce costs; they transform procurement into an engine for sustainable growth. By aligning purchasing strategies with business objectives, procurement leaders can turn supplier relationships into competitive advantages and operational data into strategic insights.

Understanding the End-to-End Procurement Lifecycle

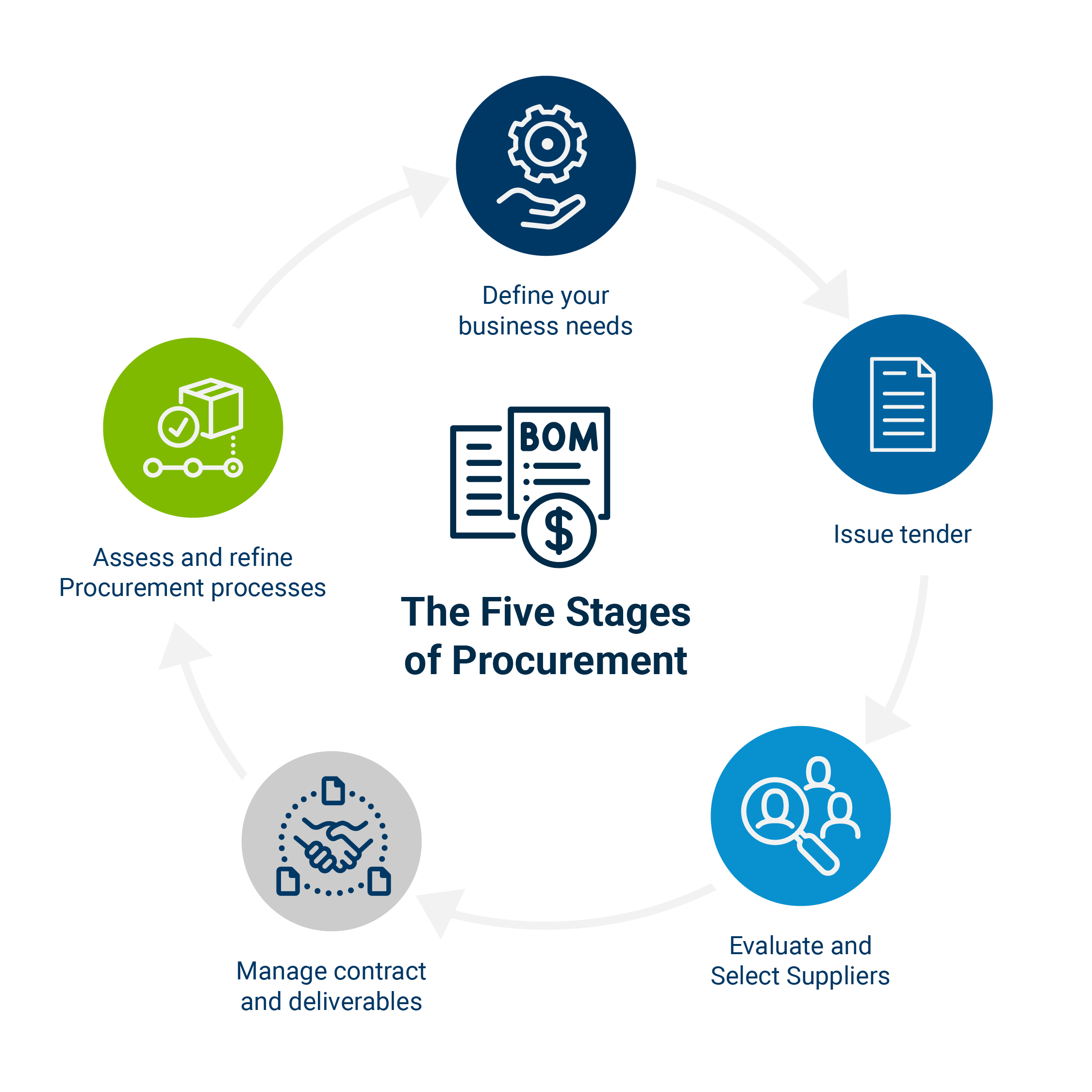

End-to-end procurement reimagines traditional purchasing by creating a connected ecosystem where each stage, from sourcing to payment, actively informs and strengthens the next. Where conventional approaches treat these functions separately, E2E procurement builds continuity across the entire process.

The benefits of this integration are substantial. Organizations gain visibility to identify cross-category efficiencies, earlier warning systems for supply chain risks, and the ability to align supplier capabilities with strategic objectives. More than just streamlining operations, this approach fundamentally changes procurement's role in the business.

Consider how the components interlock: strategic sourcing establishes the foundation, well-structured contracts capture value, automated workflows ensure execution efficiency, and proactive supplier management sustains performance. Together, they create a virtuous cycle that transforms procurement from an administrative function to a strategic driver of business results.

Strategic Sourcing and Market Analysis

The most effective procurement organizations treat sourcing as an ongoing discovery process rather than a one-time event. Procurement leaders should begin by analyzing spend patterns to identify consolidation opportunities and tail spend leakage, areas that often drain resources without adding measurable value. By targeting these inefficiencies, organizations can redirect spend toward strategic categories, negotiate stronger supplier terms, and free up capacity for initiatives that drive innovation and resilience.

This data-driven approach is complemented by continuous market scanning. For instance, Jabil's Market Intelligence Reports can provide critical visibility and material availability risks across key industries. These predictive insights enable teams to adjust strategies months before disruptions impact operations.

Category management brings structure to these efforts, with tools like the Kraljic Matrix helping teams distinguish between strategic suppliers (requiring deep collaboration) and transactional ones (where cost optimization dominates). For high-value categories, leading companies often evaluate suppliers through a total-value lens, considering innovation roadmaps and sustainability practices alongside price.

This shift from cost-focused to value-focused sourcing is what separates tactical purchasing from strategic procurement advantage.

Supplier Selection and Contract Management

Selecting the right partners requires moving beyond basic price evaluations. Progressive organizations assess suppliers through four lenses: total cost of ownership, production consistency, ability to co-develop solutions, and ESG compliance. This holistic view prevents false economies from low-bid selections.

Contracts then codify these expectations through smart KPIs and shared risk provisions. Modern agreements might include:

- Innovation milestones with joint IP ownership

- Sustainability targets with annual improvement requirements

- Market-based pricing adjustors for volatile commodities

- Clear escalation paths for service failures

These elements transform contracts from static documents into dynamic governance tools. Companies looking to implement this approach can leverage Jabil's Procurement Consulting services, which combine market intelligence with operational expertise to transform supplier relationships into strategic advantages.

Integrated Procure-to-Pay (P2P) Processes

The operational engine of E2E procurement lies in seamless P2P workflows. When requisitioning, approvals, and payments flow through automated systems, organizations achieve three critical outcomes:

- Speed: AI-powered routing cuts approval cycles from days to hours

- Accuracy: Three-way matching (POs, receipts, invoices) reduces errors by 90%+

- Insight: ERP integration provides real-time spend visibility

Best-in-class implementations go further by embedding compliance checks into workflows. For example, systems can auto-reject purchases from non-approved vendors or flag orders that exceed budget thresholds before submission.

Supplier Relationship Management (SRM)

True procurement excellence extends beyond the initial purchase to cultivate ongoing value from supplier partnerships. Leading organizations now treat SRM as a strategic discipline, one that transforms vendor transactions into competitive advantages.

These programs typically focus on three interconnected pillars that drive continuous improvement:

Performance Management

Regular scorecard reviews track quality, delivery, and innovation metrics using standardized KPIs. Top-performing suppliers gain access to joint business planning sessions and early involvement in product development, while underperformers enter structured improvement programs with clear benchmarks.

Risk Mitigation

Advanced SRM teams monitor supplier financial health, geopolitical exposures, and ESG compliance through integrated dashboards. Some now employ predictive analytics that can flag potential disruptions 6-12 months in advance, like detecting patterns that preceded previous supplier bankruptcies, enabling proactive contingency planning.

Value Creation

Innovation forums and technology road mapping sessions with strategic suppliers uncover opportunities for product improvements or cost innovations that benefit both parties.

Strategic Benefits of End-to-End Procurement

End-to-end procurement transforms purchasing from a tactical function into a strategic driver of business value. By connecting every stage, from sourcing to supplier development, organizations unlock advantages that cascade across operations:

Cost Optimization Through Visibility

The most immediate benefit comes from breaking down data silos. When procurement teams gain a unified view of spending across business units, they identify redundant suppliers, negotiate stronger volume discounts, and eliminate maverick purchases that inflate costs. Companies leading in this space often discover savings opportunities equivalent to the entire procurement department’s operating budget.

Risk Anticipation as Standard Practice

Modern procurement excels at turning hindsight into foresight. Integrated systems monitor supplier ecosystems for early warning signs, whether financial instability, regional disruptions, or compliance gaps. This allows teams to qualify alternative sources or adjust inventory strategies before crises emerge, transforming supply chains from vulnerable to resilient.

Agility That Matches Market Speed

Traditional procurement cycles struggle to keep pace with today’s volatile markets. End-to-end models change this through automated workflows that compress approval times and AI-assisted scenario planning. When material shortages or demand spikes occur, responsive organizations pivot supplier allocations or payment terms in days rather than weeks.

Supplier Relationships That Drive Innovation

The highest-performing procurement teams treat suppliers as innovation partners rather than vendors. Structured collaboration programs, from joint technology roadmaps to shared sustainability goals, consistently yield product improvements and operational efficiencies that neither party could achieve independently.

Sustainability Embedded by Design

Forward-thinking organizations now build ESG accountability into every procurement tier. Contracts increasingly mandate carbon footprint reporting, circular economy practices, and ethical labor standards, creating value chains that satisfy both regulators and conscientious consumers.

Overcoming Common Procurement Challenges

Even the most advanced procurement strategies encounter predictable roadblocks, but what separates leading organizations isn’t avoiding these hurdles, but how they navigate them.

From integration headaches to change resistance, we consistently see four challenges undermine procurement transformations:

1. System Integration Complexities

The Challenge: Legacy ERP systems, standalone sourcing tools, and department-specific databases create fragmented visibility. Procurement teams waste hours reconciling inconsistent data across platforms.

The Solution: Unified procurement platforms act as a central nervous system. By creating a single source of truth that connects with existing ERP and finance systems, organizations eliminate manual data transfers while maintaining workflow familiarity. The key is selecting adaptable solutions that scale with evolving business needs.

2. Data Security & Governance Risks

The Challenge: Expanding supplier networks and cloud-based tools create vulnerable data handoff points. Confidential pricing models, supplier IP, and compliance documentation require enterprise-grade protection.

The Solution: A tiered governance framework that:

- Standardizes access controls across all procurement applications

- Automates sensitive data redaction in supplier communications

- Conducts third-party cybersecurity audits for high-risk vendors

This approach balances security with usability, preventing protection measures from stifling operational efficiency.

3. Stakeholder Alignment Gaps

The Challenge: Finance teams prioritize cost control, operations need speed, and sustainability leaders demand ESG compliance, often creating conflicting procurement priorities.

The Solution: Cross-functional councils that:

- Co-develop procurement scorecards balancing cost, quality, and sustainability KPIs

- Host quarterly "strategy sync" sessions to align on evolving requirements

- Create rotation programs where department leads spend time in procurement (and vice versa)

When stakeholders understand procurement’s constraints and opportunities, resistance transforms into collaboration.

4. Change Management Hurdles

The Challenge: Employees accustomed to workarounds ("Just email the supplier directly!") often revert to old habits when new systems feel cumbersome.

The Solution: Behavior-based adoption strategies:

- Identify and empower procurement "champions" in each department

- Design systems that solve immediate pain points first (e.g., faster approvals)

- Measure progress through behavioral metrics (logins, tool usage) rather than just cost savings

Best Practices for Advanced Procurement Operations

Leading procurement organizations operate differently, they combine cutting-edge tools with disciplined execution to create compounding value. While technology provides the foundation, sustained success comes from embedding these practices into daily operations.

Data-Driven Decision Making

Leading procurement organizations treat data as their most strategic asset, combining AI-powered spend analytics with predictive market intelligence. They establish clean data governance upfront to ensure accuracy across all procurement categories, from direct materials to contingent labor.

Advanced teams don't just report on savings, they use machine learning to identify patterns in supplier performance, demand fluctuations, and tail spend leakage. This analytical rigor enables proactive strategy adjustments rather than reactive firefighting.

Key insight: Build your analytics roadmap backward from business outcomes, start with the decisions you need to make, then identify the data required to inform them.

Performance Management That Drives Action

The most effective procurement teams design their KPIs as leading indicators of business performance, not just operational metrics. They maintain a balanced scorecard that tracks cost savings alongside quality, innovation contributions, and risk mitigation.

Monthly business reviews bring together cross-functional stakeholders to assess trends and make joint decisions, creating organizational alignment. What sets top performers apart is their discipline in tying these metrics directly to individual and team incentives.

Key insight: Implement a "red-yellow-green" rating system for suppliers that triggers predetermined actions at each threshold, this removes subjectivity from performance management.

Continuous Capability Development

As procurement's strategic role expands, so do the required competencies. Leading organizations invest in multi-year talent development programs that combine technical training (like negotiation simulations and analytics certifications) with business immersion (through rotations in finance, operations, and product development). They create "centers of excellence" where teams pilot emerging technologies like generative AI for contract analysis before enterprise deployment.

Key insight: Develop "T-shaped" procurement professionals, deep category expertise combined with broad business acumen, through structured job rotation programs.

Built-In Sustainability

True sustainable procurement moves beyond compliance to create measurable environmental and social impact. Top organizations embed ESG considerations into every process phase, from supplier diversity targets in sourcing to carbon footprint clauses in contracts.

They work closely with suppliers to co-develop improvement roadmaps, recognizing that most sustainability impact happens upstream. Advanced teams quantify and report this impact in business terms, connecting it to brand value and customer preferences.

Key insight: Start with one material sustainability metric per category that aligns with your corporate goals, depth beats breadth when establishing credibility.

Measuring Success Holistically

Advanced procurement organizations track both operational efficiency and strategic contribution through a balanced KPI framework. Operational metrics like purchase order cycle time and cost savings capture day-to-day performance, while strategic indicators measure procurement's impact on innovation rate, supply chain resilience, and enterprise risk reduction.

Leading teams review these metrics in quarterly business reviews, adjusting priorities as organizational needs evolve. The most sophisticated functions even quantify procurement's contribution to enterprise valuation through metrics like revenue-linked supplier innovations.

Key insight: Limit your KPI dashboard to 2-3 operational and 2-3 strategic metrics, too many measures dilute focus and accountability.

Future Trends Shaping End-to-End Procurement

Procurement stands at an inflection point, where traditional cost-focused approaches will soon give way to autonomous, value-driven ecosystems. What makes this shift different from past evolutions is the convergence of three forces:

- Predictive Supplier AI: Algorithms will forecast supplier financial health and operational risks 6-12 months in advance using alternative data signals.

- Generative Contracting: AI drafters will create optimized contracts in real-time, incorporating regulatory changes and market conditions automatically.

- Blockchain Audits: Immutable ledgers will verify ESG compliance at every supply chain tier, from raw materials to finished goods.

- Autonomous P2P Systems: Self-learning procure-to-pay platforms will approve orders, resolve discrepancies, and process payments without human review for routine transactions.

- Circular Sourcing Mandates: Contracts will require minimum recycled content percentages and take-back programs for end-of-life products.

- Regionalization 2.0: "Glocal" hybrid networks will combine regional suppliers for resilience with global specialists for innovation.

- Real-Time Trade Policy Engines: Cloud platforms will instantly adjust sourcing strategies based on changing tariffs and export controls.

- Augmented Procurement Teams: AR interfaces will overlay supplier performance data during negotiations, and VR will enable immersive factory audits.

The Strategic Power of End-to-End Procurement

Industry leaders are approaching procurement as a value multiplier, connecting every supply chain touchpoint into a responsive ecosystem. This strategy delivers measurable advantages: real-time decision intelligence, collaborative supplier ecosystems, and built-in adaptability to market shifts.

When executed effectively, procurement becomes a catalyst for both operational excellence and strategic advantage.

Ready to Transform Your Procurement Strategy?

Jabil's Procurement Services provide the tools and expertise to implement a true end-to-end procurement model.

From strategic sourcing and supplier development to AI-powered procure-to-pay automation, Jabil helps businesses turn procurement into a measurable growth driver.