Why End-to-End Supply Chain Management Matters More Than Ever

July 18, 2025 | By Jabil Procurement & Supply Chain Team

Global supply chains have reached an inflection point. As production networks stretch across regions and regulations tighten, logistics strategies that once prioritized efficiency are now being restructured around resilience, traceability, and speed of execution.

End-to-end supply chain management (E2E) offers a cohesive framework to address this complexity. By linking procurement, manufacturing, logistics, and fulfillment through integrated systems and data, E2E management equips organizations to make real-time decisions, reduce operating costs, and minimize risk exposure across tiers. Instead of managing functions in isolation, teams can assess impacts holistically, adjusting for disruptions, capturing value at handoff points, and identifying opportunities for continuous improvement.

Jabil stands at the forefront of this shift, helping global manufacturers build agile, intelligent, and fully connected supply chains. With deep expertise and advanced digital capabilities, Jabil empowers customers to move from fragmented workflows to integrated, end-to-end strategies.

Here’s how end-to-end supply chain management works, and why it’s become mission-critical for global enterprises.

What Is End-to-End Supply Chain Management?

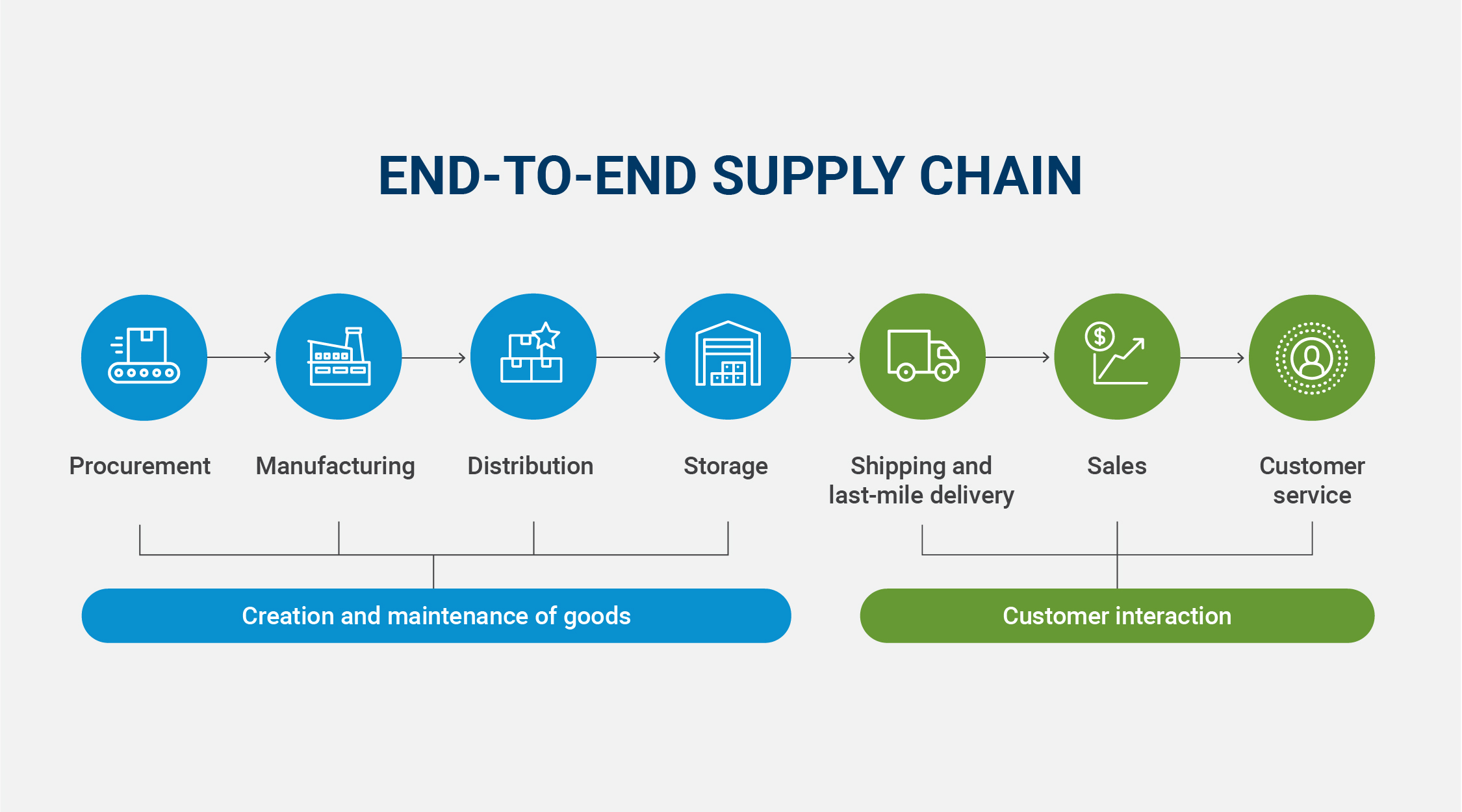

End-to-end (E2E) supply chain management is the integrated orchestration of every supply chain function, from sourcing raw materials to delivering finished products and managing post-sale services. It brings together procurement, planning, production, logistics, and fulfillment into one synchronized system built for speed, transparency, and control.

Rather than managing each stage in isolation, E2E supply chain management allows businesses to evaluate performance and risk across the full lifecycle of a product. Every decision, whether made in procurement, transportation, or demand planning, can be assessed in terms of its downstream and upstream impact, enabling smarter, faster responses to market changes and operational risks.

How E2E Differs from Traditional Supply Chain Models

Traditional supply chains are often managed in functional silos. Procurement negotiates contracts. Operations oversees production. Logistics manages delivery. Each group optimizes for its own KPIs, often without visibility into how their actions affect other stages of the supply chain.

E2E supply chain management dismantles those silos by connecting workflows and data across functions and partners. Teams no longer operate on assumptions or lagging reports, they plan and adjust using real-time intelligence that reflects the full chain of activities. This shift from fragmented oversight to unified decision-making is what gives E2E systems their strategic edge.

Key Objectives of End-to-End Supply Chain Management

Organizations embracing E2E supply chain management aim to achieve four foundational goals:

- Streamlined Processes: Remove redundancies, improve handoffs, and accelerate throughput across all logistics and planning functions.

- Real-Time Visibility: Gain full transparency into supplier performance, inventory levels, and demand signals, no matter how far upstream or downstream they occur.

- Comprehensive Control: Empower cross-functional teams to coordinate proactively, rather than reactively, with shared data and automated workflows.

- Resilience and Agility: Build supply chains that can adapt to disruption without sacrificing service quality or margin performance.

Core Components of End-to-End Supply Chain Management

True end-to-end supply chain management hinges on the seamless integration of functions that have traditionally operated in silos. Each stage must be orchestrated with a shared goal: real-time visibility, operational agility, and synchronized execution from planning to customer delivery.

Below are the foundational components of a well-structured E2E supply chain:

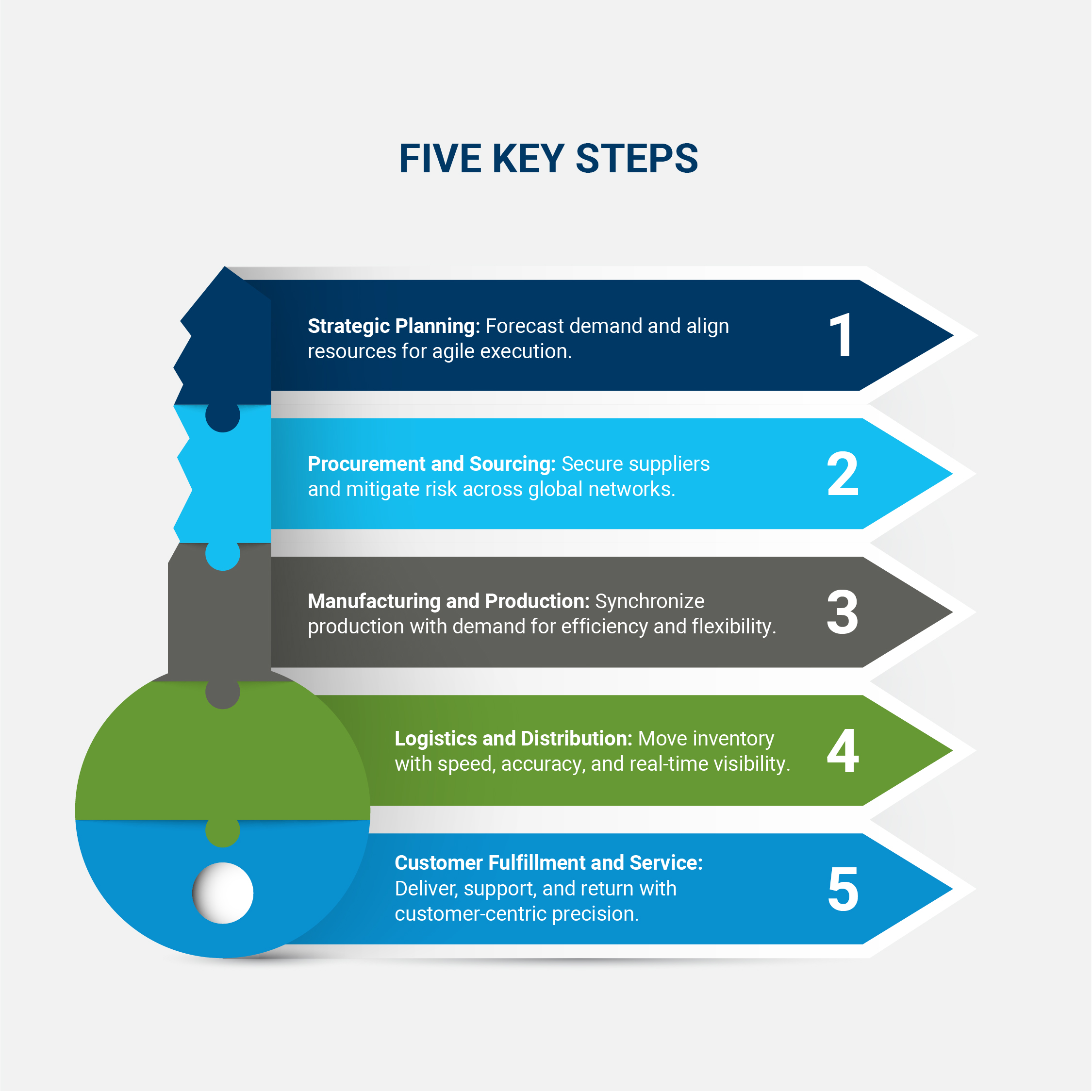

Strategic Planning

Strategic planning sets the tone for execution across the supply chain. It involves forecasting future demand, allocating resources, and aligning capacity to business objectives.

Advanced planning tools and predictive analytics help teams identify bottlenecks before they emerge and ensure supply aligns with demand across every node in the network. For instance, Jabil’s Market Intelligence Reports can support this process with forward-looking insights on component availability, regional risks, and sourcing trends across key industries.

To execute strategic planning effectively, companies must excel in three core areas:

- Demand Forecasting and Planning: Use of AI-driven models to anticipate market shifts and adjust procurement and production accordingly.

- Capacity and Resource Allocation: Planning labor, equipment, and production lines around real-time data to improve service levels and responsiveness.

- Strategic Supplier Relationships: Early supplier involvement and long-term partnerships that strengthen resilience and reduce sourcing volatility.

Procurement and Sourcing

The procurement function must evolve from cost-centric negotiations to a value-driven, risk-aware process that ensures continuity, compliance, and supplier diversity. In an E2E supply chain, effective procurement is not just about securing parts, it’s about building resilience and agility from the ground up.

- Supplier Selection and Qualification: Vetting suppliers not just for price, but for ESG practices, agility, and digital readiness.

- Contract Negotiation and Purchasing: Leveraging dynamic contracts that accommodate volume fluctuations and pricing triggers.

- Risk Management and Diversification: Multi-sourcing strategies and scenario modeling to minimize dependency on single geographies or vendors.

Manufacturing and Production

Manufacturing needs to operate as a flexible, demand-driven engine. When connected to procurement and logistics through an E2E framework, production becomes a synchronized lever for responsiveness and efficiency.

-

Production Scheduling and Optimization: Real-time production planning systems that sync with downstream logistics and upstream procurement.

-

Inventory Strategies (JIT vs. JIC): Balancing just-in-time efficiency with just-in-case buffers to protect against disruption.

-

Continuous Improvement: Embedding Six Sigma, Kaizen, and other quality control practices to drive operational excellence.

Logistics and Distribution

Efficient logistics execution is a linchpin of customer satisfaction and profitability. From global freight coordination to last-mile delivery, E2E logistics ensures inventory moves where it’s needed, when it’s needed. Jabil’s Logistics Management Services offer technology-driven solutions that can help companies streamline distribution, enhance visibility, and reduce transportation costs across complex networks.

- Transportation Management: Real-time visibility, load optimization, and TMS integration to minimize lead times and costs.

- Inventory Visibility: Unified systems that track inventory across warehouses, transit, and channels for proactive replenishment and fulfillment.

- Last-Mile and Cross-Docking Solutions: Agile distribution models that compress delivery windows and reduce warehouse dwell time.

Customer Fulfillment and Service

The customer experience doesn’t end at the point of sale. An E2E supply chain ensures that fulfillment, returns, and service are treated as interconnected levers for loyalty and long-term value.

- Order and Fulfillment Management: Coordinated workflows across ERP, WMS, and OMS platforms to reduce order errors and accelerate delivery.

- Customer Service Integration: Linking logistics and service systems to deliver accurate status updates, seamless support, and warranty coordination.

- Reverse Logistics and Returns: Efficient, low-cost return management that feeds insight back into product design and inventory forecasting.

Strategic Benefits of End-to-End Supply Chain Management

As global volatility, evolving customer expectations, and tightening regulations reshape the supply chain landscape, end-to-end supply chain management has emerged as a strategic imperative. By integrating systems, teams, and data across every function, businesses can turn fragmented operations into a coordinated engine for value creation and competitive advantage.

When implemented effectively, E2E supply chain management delivers measurable business value across four key areas:

Enhanced Resilience

Integrated supply chains are better equipped to anticipate and respond to disruptions, whether it’s a supplier shutdown, weather event, or geopolitical shock. End-to-end visibility enables earlier detection of risk and faster course correction across sourcing, production, and logistics.

As supply chains face increasing volatility, enhancing risk mitigation has become central. In fact, a Jabil 2024 Supply Chain Resilience survey found that nearly half (49%) of supply chain and procurement leaders identified risk mitigation and flexibility as a main organizational goal, underscoring the strategic shift toward proactive, resilient supply chain management.

Greater Efficiency and Cost Savings

A unified approach eliminates process redundancies, minimizes excess inventory, and improves forecasting accuracy. With tighter alignment between procurement, production, and delivery, companies can reduce operating costs while improving throughput.

Improved Customer Satisfaction

Seamless coordination across the supply chain ensures timely order fulfillment, accurate tracking, and responsive after-sales service. These capabilities help companies deliver a more reliable, transparent customer experience that drives long-term loyalty.

Stronger Regulatory and ESG Compliance

Real-time data and traceability across multi-tier networks allow businesses to meet growing demands for sustainability, ethical sourcing, and global compliance. Companies can document practices, measure progress, and ensure accountability across the value chain.

Challenges in End-to-End Supply Chain Management, and How to Solve Them

While the benefits of end-to-end supply chain management are well-established, implementation can be complex. Organizations must address both technical and organizational hurdles to realize the full value of integration.

Understanding these challenges, and how to overcome them, is key to building a scalable, future-ready supply chain:

Integration Complexities

Merging siloed systems, partners, and workflows across functions often reveals gaps in legacy architecture and data compatibility. The solution lies in deploying robust integration platforms and cloud-based control towers that unify data sources without major system overhauls.

Data Quality and Security Risks

Real-time visibility requires consistent, trustworthy data, yet many supply chains operate with fragmented or outdated information. Building data governance frameworks and investing in cybersecurity tools can help ensure accuracy, traceability, and protection across networks.

Cross-Functional and Cross-Tier Alignment

Operational silos and misaligned KPIs across business units and suppliers can derail coordination efforts. Establishing shared metrics, accountability models, and communication protocols, supported by executive buy-in, is essential to driving unified decision-making.

Workforce Readiness and Change Management

The shift to end-to-end logistics requires more than new tools; it demands new ways of thinking. Companies must invest in continuous training, upskill teams in data literacy, and create a culture that embraces transparency, agility, and innovation.

Best Practices for Successful E2E Supply Chain Execution

Implementing end-to-end supply chain management isn’t just about deploying new tools. It’s about designing a system that can evolve with your business. Leading companies follow a series of proven practices to ensure long-term performance, resilience, and scalability.

The following strategies represent common threads among top-performing supply chains that have successfully scaled E2E capabilities across regions, partners, and product lines:

Define the Metrics That Matter

Success starts with clarity. Establish cross-functional KPIs that reflect not only cost and speed, but also customer satisfaction, risk mitigation, and sustainability. Make sure performance benchmarks are visible, measurable, and updated regularly to reflect evolving business priorities.

Build on Flexible Technology

Rigid systems don’t scale. Invest in cloud-based infrastructure and modular platforms that integrate seamlessly with partners, legacy systems, and emerging tools. Solutions like Jabil’s Procurement Technology Services can help centralize spend data, automate sourcing, and integrate procurement systems into broader E2E workflows.

Adopt a Continuous Improvement Mindset

Static supply chains fall behind. Incorporating Lean, Six Sigma, and Agile methodologies encourages a culture of testing, learning, and iterating. These frameworks help teams root out inefficiencies, increase precision, and stay aligned as conditions evolve.

Engage Stakeholders at Every Level

Alignment doesn’t happen automatically. Establish structured communication channels between procurement, logistics, manufacturing, and customer service, along with external suppliers and partners. Regular engagement ensures that strategy, execution, and insights are moving in sync across the entire chain.

Advanced Technologies and Future Trends in E2E Supply Chain Management

The future of supply chain management is being shaped by a wave of innovation and geopolitical change. Forward-thinking organizations are adopting these trends to improve efficiency and future-proof their supply chains in a world defined by volatility, complexity, and digital acceleration.

These emerging technologies and macro shifts are redefining what’s possible, and expected, in modern supply chain operations:

- Real-Time Visibility and AI Integration: AI and IoT tools enable predictive planning, dynamic routing, and real-time decision-making. In fact, 66% of companies now use predictive analytics or AI to strategically manage their supply chains.

- Blockchain for Transparency and Trust: Decentralized ledgers provide secure, auditable tracking of goods, improving traceability and compliance across global networks. This is especially useful in sectors like pharmaceuticals and electronics, where blockchain ensures authenticity and verifies ethical sourcing across multiple tiers.

- Automation, Robotics, and Autonomous Solutions: Technologies like autonomous mobile robots (AMRs) and warehouse robotics boost speed and accuracy while reducing reliance on manual labor. Retailers and 3PLs are increasingly deploying automated picking and packing systems that process thousands of orders per hour with minimal error.

- Sustainability and Circular Economy: Reverse logistics, material reuse, and emissions tracking are gaining ground as companies design regenerative supply chain systems. Many manufacturers are now using recycled inputs in production and leveraging digital twins to model carbon impact across their supply networks.

- Global Economic Shifts and Adaptation: Volatility is driving more localized, flexible networks. Digital infrastructure is critical for rapid reconfiguration and risk mitigation. In response to geopolitical tensions, businesses are expanding nearshoring strategies and diversifying supplier footprints to reduce exposure.

Ready to Elevate Your Supply Chain?

End-to-end supply chain management is becoming the standard for enterprises operating in today’s dynamic global economy.

Whether you’re aiming to strengthen resilience, reduce costs, or meet complex compliance demands, building a connected, transparent, and adaptive supply chain is key to staying ahead.

Jabil’s procurement and supply chain services are purpose-built to support this transformation. From strategy to execution, we help global manufacturers turn complexity into competitive advantage.