Procurement Optimization That Drives Efficiency and Resilience Across Industries

January 19, 2026 | By Jabil Procurement & Supply Chain Team

Every organization is navigating a new kind of complexity, supply volatility, rising costs, rapid innovation cycles, and escalating sustainability expectations. In this environment, procurement optimization has emerged as a universal strategy for stability and growth.

Whether the goal is accelerating digital transformation, reducing risk exposure, advancing ESG priorities, or reshaping supplier ecosystems, optimized procurement provides the intelligence and control to move faster with greater confidence.

Far from a single initiative, procurement optimization brings together people, processes, and technology to create a more connected, predictive, and resilient operation. It allows teams to see deeper into their value chains, adapt sourcing strategies in real time, and build partnerships that strengthen competitive advantage.

At Jabil Procurement & Supply Chain Services (PSCS), our practitioner-led teams apply firsthand manufacturing and sourcing expertise to help organizations unlock this potential, transforming procurement into a strategic platform that drives agility, innovation, and long-term value across industries.

Procurement Optimization: Definition & Goals

Procurement optimization represents a shift toward smarter, more connected procurement. It’s about turning the purchasing function into a strategic system that drives resilience, visibility, and enterprise value, connecting people, processes, and data to work in sync across the entire organization.

- Procurement Optimization: The strategic enhancement of end-to-end procurement processes to reduce cost, risk, and cycle time while improving compliance, supplier value, and alignment with business and ESG goals.

By focusing on procurement process optimization and procure-to-pay optimization, organizations can strengthen decision-making, automate compliance, and create a continuous improvement loop that ties procurement activity directly to business performance.

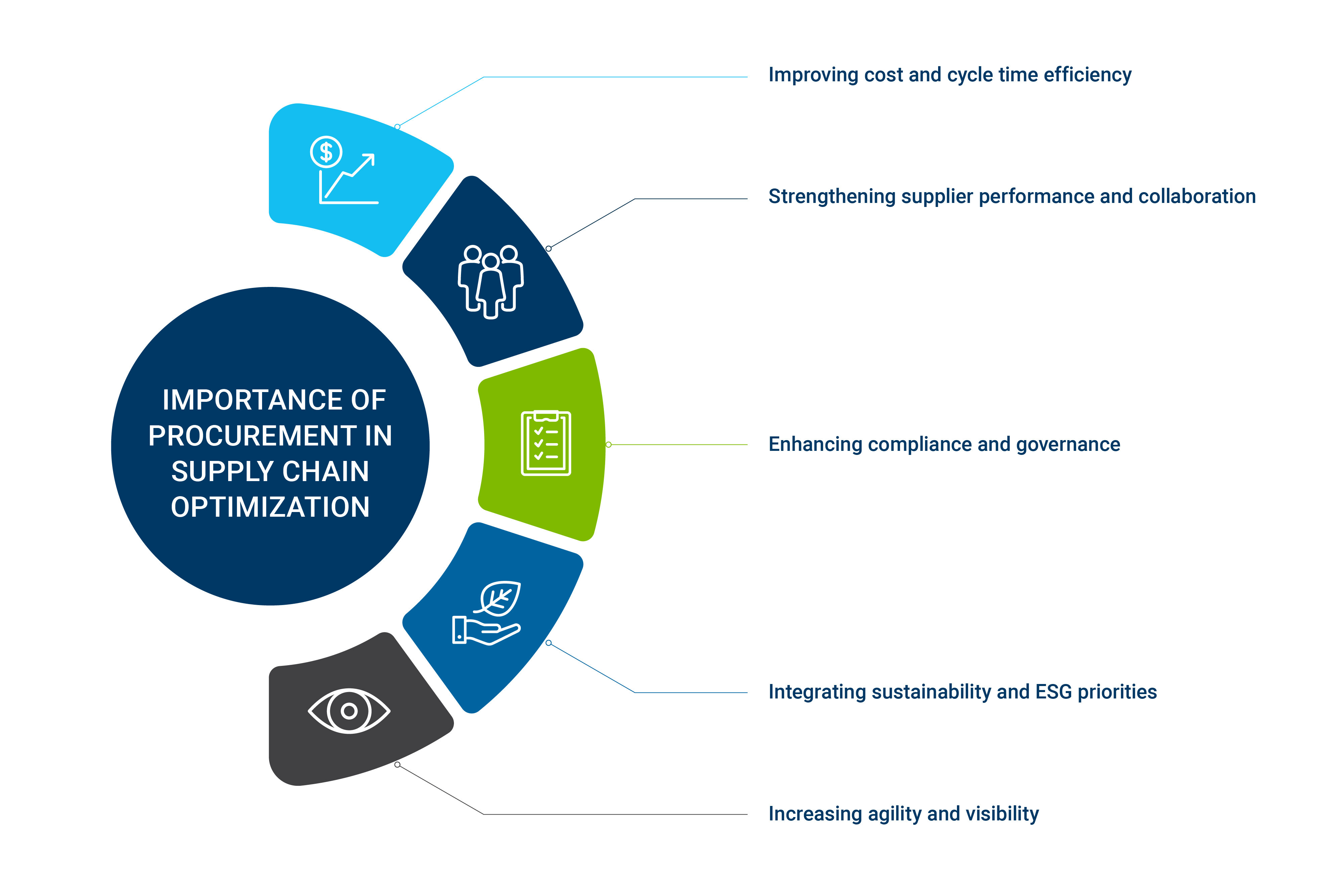

Core goals of procurement optimization include:

- Improving cost and cycle time efficiency to streamline the procure-to-pay process and reduce operational delays.

- Strengthening supplier performance and collaboration to enhance quality, reliability, and long-term value creation.

- Enhancing compliance and governance to promote transparency, accountability, and regulatory alignment.

- Integrating sustainability and ESG priorities to advance responsible sourcing and corporate citizenship.

- Increasing agility and visibility to enable faster, data-driven decisions across global operations.

Jabil’s Procurement Consulting experts help organizations benchmark their current procurement maturity, define measurable optimization goals, and align processes with enterprise-wide digital transformation strategies.

How It Fits into Supply Chain Performance

Procurement doesn’t operate in isolation. Rather, it’s the foundation of a responsive, resilient supply chain.

By tightening process controls and unifying data across sourcing, logistics, and finance, organizations can forecast demand more accurately, improve supplier collaboration, and safeguard continuity. The payoff is tangible, shorter lead times, fewer disruptions, and real-time visibility that empowers smarter, faster decisions when conditions change.

Key Elements of Procurement Optimization

Procurement optimization depends on a connected ecosystem of processes, technologies, and performance metrics. The following elements define how leading organizations create measurable improvement across cost, compliance, and supplier value while building resilience into every stage of the procurement lifecycle.

Process Analysis & Benchmarking

Optimization begins with a clear understanding of where procurement stands today. Process analysis and benchmarking help organizations evaluate efficiency, compliance, and value delivery across the entire source-to-pay cycle. By applying procurement maturity models and external benchmarks, teams can identify capability gaps and set realistic targets for continuous improvement.

Common KPIs include purchase order (PO) cycle time, percentage of touchless invoices, spend under management, maverick spend percentage, and contract compliance rate. Tracking these indicators enables procurement leaders to measure progress and tie optimization efforts directly to business performance.

Strategic Sourcing & Supplier Collaboration

Strategic sourcing and supplier performance optimization extend far beyond price negotiation. Leading organizations design category strategies that span direct, indirect, logistics, and CAPEX spending, supported by Supplier Relationship Management (SRM) tools that consolidate performance data and communication.

Suppliers should be evaluated against key metrics such as on-time in-full (OTIF) delivery, quality, and cost performance to drive accountability and transparency. Collaborative sourcing models and digital SRM platforms enable proactive engagement, helping organizations mitigate risk, improve innovation, and strengthen long-term supplier partnerships.

Automation & Digital Transformation Tools

Automation can transform procurement from reactive to predictive. Technologies like AI, robotic process automation (RPA), and procure-to-pay (P2P) systems streamline requisitions, approvals, and invoice matching, allowing procurement teams to focus on strategy instead of administration.

When these tools connect seamlessly with ERP and master data systems, they create a foundation for touchless procurement, reducing manual effort, improving data accuracy, and accelerating cycle times. Supported by Jabil’s Procurement Technology Services, organizations can implement and integrate these technologies more effectively, ensuring end-to-end visibility and sustainable digital transformation.

Performance Visibility & Analytics

Visibility is what turns procurement data into business intelligence. Real-time dashboards and predictive analytics tools track spending, supplier risk, and operational performance across categories. Procurement teams use spend cubes, should-cost modeling, and KPI visualization to uncover savings opportunities, assess risk exposure, and forecast demand. The result is a transparent, data-driven ecosystem that continuously optimizes itself.

Benefits of Procurement Optimization

Procurement optimization can deliver measurable business impact by aligning efficiency, transparency, and strategic control. From lowering total cost of ownership to improving delivery reliability and governance, its benefits extend across every layer of the supply chain.

Cost Savings & Improved Margins

Optimization drives cost reduction through smarter sourcing and better visibility into total cost of ownership (TCO). Automated spend analysis and predictive forecasting uncover savings opportunities, while process efficiency improves working capital through early-pay discounts and optimized days payable outstanding (DPO). Together, these capabilities enable finance and procurement teams to protect margins and reinvest savings into growth.

Streamlined Operations & Faster Lead Times

Automation and process standardization shorten cycle times from requisition to payment. By removing manual bottlenecks, organizations can accelerate sourcing, approvals, and order fulfillment, improving delivery reliability across suppliers and categories. Optimized workflows ensure teams spend less time managing transactions and more time managing performance.

Improved Data Integrity & Visibility

Centralized data and integrated systems create a single source of truth for procurement. With unified platforms linking spend, supplier, and contract data, teams gain end-to-end visibility into every transaction. This integrity empowers faster decisions, stronger governance, and real-time performance tracking.

Better Customer Satisfaction Through Reliable Delivery

Procurement optimization strengthens supply continuity and delivery performance by ensuring materials arrive on time, every time. Improved forecasting, inventory alignment, and supplier collaboration enhance on-time in-full (OTIF) rates, supporting dependable production and customer satisfaction.

Risk Management & Compliance Assurance

Automated compliance checks and digital audit trails safeguard against operational and reputational risks. Optimization platforms monitor ESG adherence, supplier certifications, and regulatory standards while scoring supplier risk in real time. This proactive approach reduces exposure, enhances accountability, and supports transparent, ethical sourcing.

Challenges in Procurement Optimization (and How to Overcome Them)

Even the most advanced procurement programs encounter barriers that limit scalability, visibility, and adoption. Overcoming these challenges requires a mix of digital transformation, data discipline, and organizational change.

Common challenges include:

- Legacy Systems and Manual Processes: Fragmented ERP, CLM, and SRM systems create data silos that slow procurement cycles and obscure visibility. Adopting automation-first architectures and integrating RPA or procure-to-pay (P2P) systems can streamline operations and eliminate redundant workflows.

- Poor Supplier Collaboration: Without transparent communication and aligned goals, supplier relationships remain transactional. Implementing Supplier Relationship Management (SRM) platforms, performance scorecards, and regular quarterly business reviews (QBRs) promotes accountability, innovation, and mutual growth.

- Resistance to Change Within Organizations: Transformation often fails when teams struggle to adopt new tools or processes. Overcoming this requires structured change management, clear adoption metrics, and reskilling programs that help employees embrace digital capabilities and new ways of working.

- Data Quality and Governance Gaps: Inconsistent or incomplete data undermines decision-making and limits predictive analytics. Establishing strong data governance frameworks, cleansing legacy datasets, and centralizing spend information ensure a reliable foundation for optimization.

- Limited Visibility Across Tiers: Many organizations still lack insight beyond Tier 1 suppliers, leaving them vulnerable to hidden risks. Integrating supplier mapping tools and AI-driven risk monitoring helps identify vulnerabilities, diversify sourcing, and maintain supply continuity.

- Siloed KPIs and Misaligned Metrics: When finance, logistics, and procurement measure success differently, optimization stalls. Aligning KPIs, such as cycle time, contract compliance, and working capital, across departments ensures shared accountability and continuous improvement.

Procurement optimization succeeds when organizations address these barriers holistically, uniting people, technology, and governance to build a foundation for lasting resilience and efficiency.

Best Practices for Procurement Optimization

Procurement optimization succeeds when strategy, technology, and performance discipline work together. The following best practices form a roadmap for transforming procurement into a connected, data-driven, and resilient business function.

Supplier Evaluations & Continuous Improvement

Strong supplier relationships begin with structured evaluations and transparent performance metrics. Organizations should use supplier scorecards to track on-time delivery, quality, and responsiveness, while benchmarking helps identify top performers and development opportunities. Continuous improvement programs, such as joint process reviews or capability-building initiatives, drive supplier innovation and resilience. When paired with Supplier Relationship Management (SRM) tools, these practices enable more consistent performance, reduced risk, and shared value creation.

Leveraging Technology (Automation, AI, SRM Tools)

Digital transformation is the cornerstone of procurement optimization. AI enhances forecasting accuracy and identifies savings opportunities; RPA automates repetitive processes like invoice matching and purchase order creation; and generative AI (GenAI) accelerates contract drafting and risk analysis. Leading organizations implement touchless invoicing, integrated analytics dashboards, and seamless ERP connectivity to improve data flow and eliminate manual work. The result is faster decision-making, higher compliance, and a more strategic, insight-driven procurement function.

Strategic Negotiations with Market Intelligence

Data-driven negotiations redefine how companies capture value. Procurement teams use should-cost modeling, clean-sheet analysis, and real-time commodity forecasting to negotiate based on facts, not assumptions. Integrating market intelligence tools enables predictive sourcing, anticipating price fluctuations and supplier capacity shifts before they occur. This analytical approach leads to stronger, more transparent supplier agreements and sustainable cost advantages.

Embedding Sustainability & ESG in Procurement

Procurement optimization is increasingly tied to corporate sustainability. Embedding ESG metrics into sourcing decisions helps organizations measure supplier carbon impact, ensure ethical sourcing, and monitor Scope 3 emissions with greater accuracy. These practices not only support regulatory compliance but also build trust across the value chain.

A Practical Roadmap for Optimization

Procurement optimization evolves in stages, each building on the last to deliver greater efficiency, visibility, and strategic control:

- Operate: Standardize core workflows and measure performance (PO cycle time, contract compliance, automation rate).

- Reconfigure: Integrate digital tools, consolidate suppliers, and embed spend analytics for visibility and control.

- Transform: Use predictive analytics, AI, and advanced KPIs to achieve continuous improvement and agility.

Procurement maturity typically moves from Ad Hoc → Managed → Optimized → Predictive, with each stage bringing deeper automation and integration. Organizations that follow this path achieve measurable gains in compliance, performance, and value creation. Partnering with a trusted provider like Jabil helps organizations sustain momentum and scale results, with Procurement Managed Services that maintain optimization and performance over time.

The Future of Procurement Optimization

Procurement is evolving faster than ever. Emerging technologies and operating models are reshaping how organizations manage cost, risk, and performance, turning procurement into an intelligent, predictive function that drives long-term competitiveness.

Predictive Analytics & AI Forecasting

Procurement teams are beginning to leverage predictive analytics and AI to anticipate what’s next rather than react to what’s happened. These tools forecast demand fluctuations, commodity cost changes, and supplier risks by analyzing patterns across global markets, production data, and logistics signals. This enables proactive decision-making, like adjusting sourcing before a shortage hits or renegotiating contracts ahead of inflationary swings.

How to prepare: Start centralizing procurement and supply data into integrated analytics platforms. Build predictive models around top spend categories and use pilot projects to identify early wins in forecasting and cost control.

Blockchain for Supplier Transparency

Blockchain is redefining trust in supplier networks. By creating immutable transaction records and enabling smart contracts, companies gain end-to-end visibility into where materials come from, how they’re produced, and whether suppliers meet ethical and environmental standards. This traceability helps reduce fraud, enhance compliance, and validate ESG claims.

How to prepare: Begin with blockchain-enabled supplier verification for high-risk categories and expand into digital contract execution for improved transparency and speed.

Agile Procurement Strategies in Volatile Markets

Future-ready organizations are adopting agile procurement, combining flexible sourcing with regional diversification and digital twins to simulate supply disruptions. Nearshoring and multi-tier mapping create the responsiveness needed to handle rapid market shifts without compromising quality or service.

How to prepare: Reassess sourcing footprints and establish regional alternatives for critical materials. Use digital twin modeling to evaluate “what-if” disruption scenarios and optimize response plans.

FAQs on Procurement Optimization

How does procurement optimization support digital transformation initiatives?

Optimizing procurement helps connect data, systems, and teams, creating the foundation for digital transformation. With better visibility and automation, organizations can make faster, smarter decisions that drive enterprise-wide efficiency.

What’s the difference between procurement optimization and spend management?

Spend management focuses on tracking and controlling what’s already been spent. Procurement optimization goes further, improving how organizations source, negotiate, and manage suppliers to create long-term value.

How can mid-sized organizations begin their procurement optimization journey?

Start small by mapping key processes, automating repetitive tasks, and organizing supplier data. As those systems mature, adding analytics and AI tools can unlock deeper insight and scalability.

What are early indicators that a procurement optimization initiative is succeeding?

Shorter purchase order cycles, fewer manual steps, and better supplier performance are strong early signs of success. You’ll also see improved spend visibility and stronger compliance across the organization.

How can procurement teams balance cost optimization with sustainability goals?

By building sustainability metrics into sourcing decisions, teams can reduce both costs and environmental impact. Choosing suppliers who align with ESG goals strengthens resilience while protecting margins.

Why Partner With Jabil for Procurement Optimization

Procurement optimization requires more than technology, it demands global visibility, scale, and expertise. Jabil Procurement & Supply Chain Services (PSCS) combines practitioner-led insight with advanced digital tools to help organizations transform procurement into a strategic advantage.

Connect with Jabil’s procurement experts to see how optimization accelerates savings, visibility, and resilience across your supply chain.